Blog

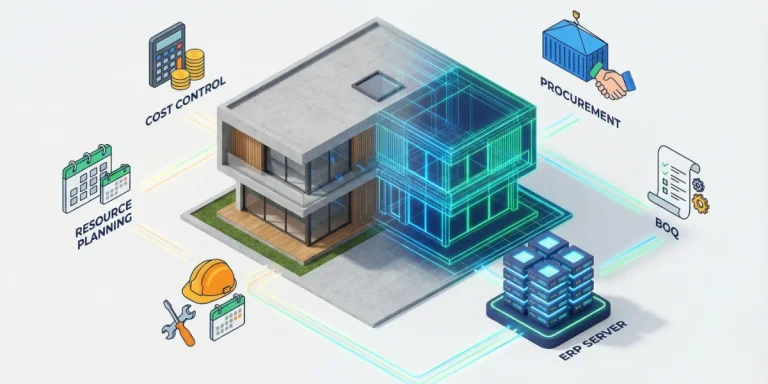

For project-based firms, ERP for Construction Companies has become a strategic necessity in the face of increasing cost pressures, complex field operations, and time management challenges. Managing multiple construction sites, fluctuating bill of quantities (BOQ) items, and intensive resource utilization makes it difficult to control processes through manual methods. At this point, ERP systems strengthen…

ERP for the Textile Industry provides a critical digital infrastructure for textile companies to manage their operations sustainably in the face of increasing competition, short lead-time pressures, and high-variant production structures. The prevalence of subcontracted production networks, the increasing number of collections, and rapidly changing customer demands have made it nearly impossible to manage production,…

Material Requirements Planning (MRP) with ERP is a strategic approach that unites planning and control processes in a single center, developed to enable manufacturing enterprises to use their resources more efficiently. By evaluating critical data such as production plans, inventory levels, procurement processes, and lead times through the MRP system, the goal is to prevent…

The food industry is one of the most complex sectors to manage, governed by vital factors such as quality, speed, traceability, and legal compliance in both production and distribution. It requires precise control at every step—from the supply chain and production to inventory management and sales. Consequently, Enterprise Resource Planning (ERP) systems are no longer…

Enterprise Resource Planning (ERP) systems liberate supply chain and procurement management from manual processes, moving them toward a digital, traceable, and integrated structure. In today’s business world—where competition, speed, and efficiency are decisive—digitizing procurement with ERP provides more than just operational convenience; it offers a strategic advantage. With over 35 years of experience, an open-source…

The question of “How to use ERP for inventory and warehouse management?” is a critical topic in today’s business world, where enterprises of all sizes—from manufacturing to retail—aim for efficiency and cost optimization. Accurate inventory management is vital for balancing cash flow, increasing customer satisfaction, and preventing unnecessary costs. Integrated enterprise resource planning systems, such…

The question of “What should be considered when selecting an ERP system?” is of strategic importance for every business stepping into the digital transformation process. Choosing the right ERP directly affects not only the automation of business processes but also fundamental elements such as efficiency, cost control, sustainability, and competitiveness. An ERP solution that aligns…

Enterprise Resource Planning (ERP) systems and accounting programs are two fundamental tools used to manage financial processes. However, these two concepts are frequently confused. In reality, the difference between them is significant enough to determine the maturity level of a business’s digital transformation journey. At Canias, with over 35 years of experience in digital transformation,…

Enterprise Resource Planning (ERP) is a comprehensive software system used to manage all core business processes of an enterprise in an integrated manner. ERP systems consolidate various functions—such as accounting, procurement, project management, risk management, regulatory compliance, supply chain management, and production planning—under a single roof. Consequently, companies achieve significant advantages in data integrity, operational…

The Role of ERP in Digital Transformation and Its Importance for SMEs Digital transformation has become essential for SMEs to enhance competitiveness and ensure sustainable growth. ERP systems play a critical role in this journey by offering advantages that support the digitization of business processes. So, what is ERP, and what are its benefits in…

In today’s business world, sustainability has become more than just an obligation; it is now a fundamental element that provides companies with a competitive advantage. The necessity to fulfill environmental responsibilities while achieving economic growth targets is leading enterprises to seek new solutions. At IAS, to stand by and support companies on their sustainability journey,…

Digitalization has rapidly become a transformative process that affects business operations in nearly every sector of today’s world. If you are curious about how to leverage digitalization to optimize business processes and increase efficiency as you embark on your digital transformation journey, you’re in the right place. In this article, we will explore how you…

A concept ever-present in our business lives, risk can be defined as an uncertain element or outcome involving harm, loss, or danger. In other words, Risk is the probability of something having a negative impact on objectives. There can be many risks in your business and its processes. These risks should be properly managed to…

You have sales orders, you have received your forecasts, you have determined your independent demands, in other words, your systemic demands have been determined in general. Let’s say you have the basic datas of the products, such as the BOM, the routes, as well as the parameters that affect material requirement planning, like safety stocks…

Enterprise Resource Planning (ERP) systems offer comprehensive solutions that enable business processes to be managed more efficiently and effectively by integrating them into a centralized platform. Understanding the wide range of application areas and benefits provided by ERP applications, alongside the unique advantages of Canias ERP, helps organizations make informed decisions when selecting their digital…

ERP (Enterprise Resource Planning) is a software system used to manage the daily business activities and departmental processes of companies. It integrates operational transactions—such as sales, procurement, production planning, manufacturing, and shipping—with the business processes of departments including accounting, finance, import-export, human resources, R&D, quality assurance, and engineering. The History of ERP The 1970s and…

The origins of ERP systems can be traced back to MRP (Material Requirements Planning) software. The subsequently developed system, known as MRP II, was defined as Manufacturing Resource Planning. Thus, a system that was previously used solely for planning material requirements evolved toward planning production requirements, expanding the scope of the business operations. Following MRP…

ERP solutions are systems aimed at the optimum utilization of an enterprise’s existing resources. They serve to record and preserve all types of information and documents that are valuable or potentially valuable—providing added value today or in the future—within a centralized system. ERP software contains an “experience pool” designed to provide solutions for problems that…